Services

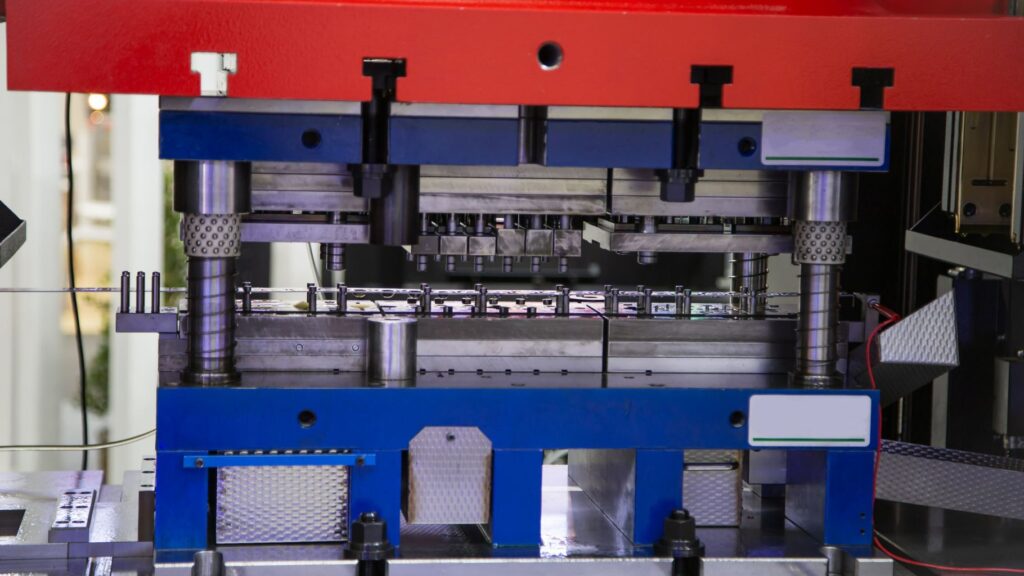

Refurbishment Of Hydraulics Machines with Servo Technologies

- Refurbishment of Hydraulic Press and Injection molding machines.

- This new technologies helps in 50-60% power savings results.

- We provide complete motion controller solution for Synchronization, Force and Position Control, Pressure & Speed Control.

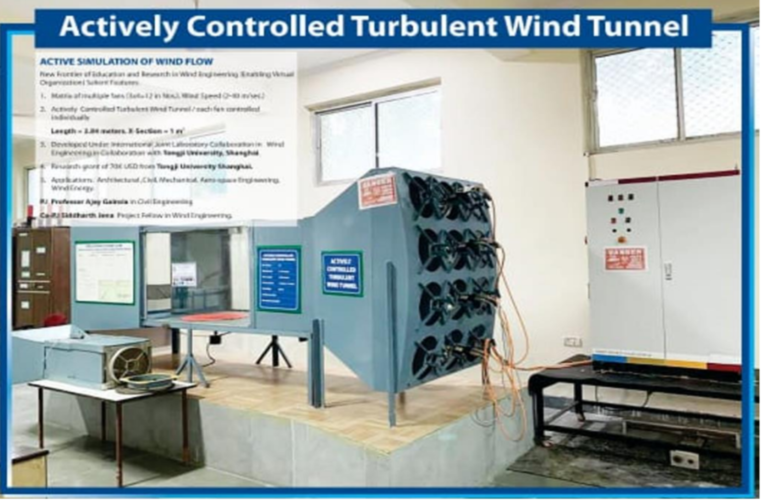

Research and Testing Solutions

- Designing and developing of wind tunnel based on testing requirement.

- Wind control is up to 40m/s max.

- Multi fan and Single fan wind tunnel designed

- DAQ – Data Acquisition system

- Analysis of Data by using Labview and other analytical software

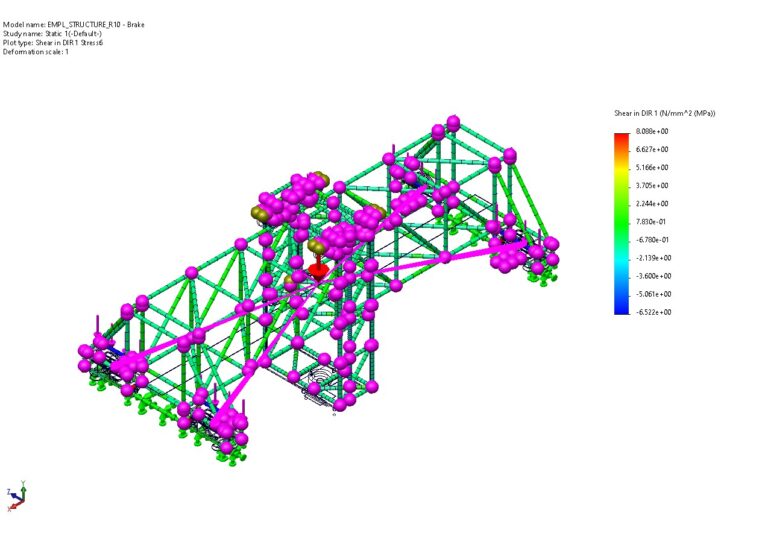

Designing of Structure and Machines with FEA analysis

- Special machine Design and Analysis.

- Calculation of mechanical part like, Strength of Material, Shear force, Bending moment, Torsional force Torsional Moment.

- Designing and calculation according to Seismic condition, Arial force and Waves.

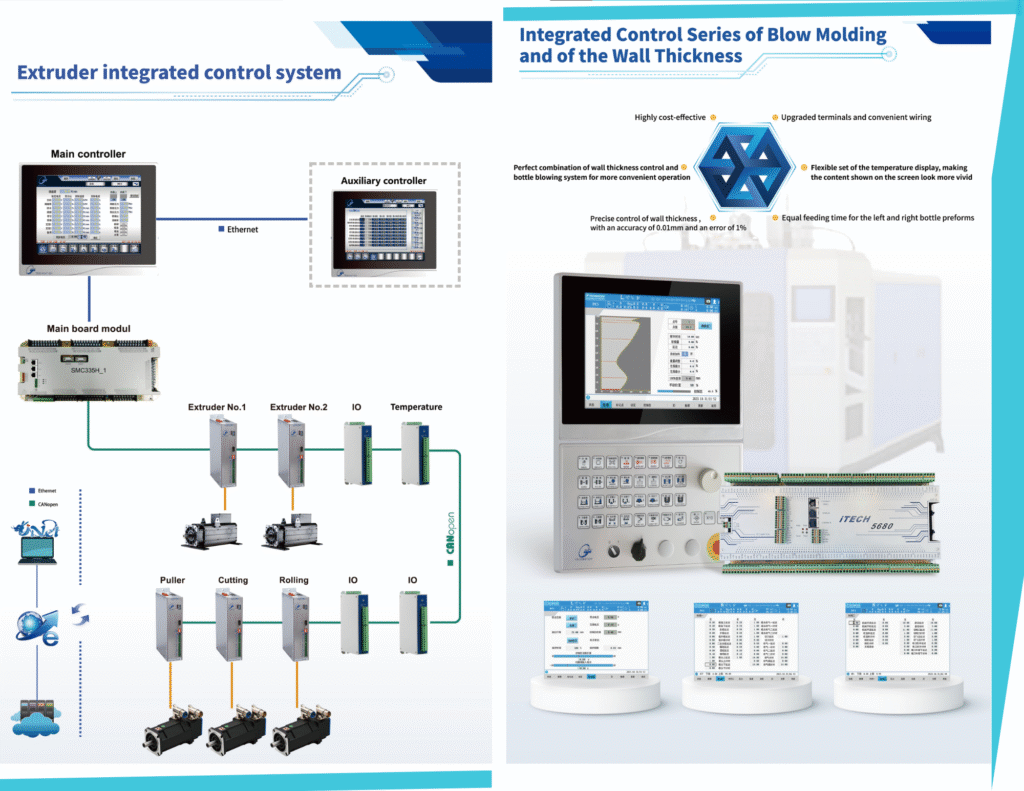

Extruder Integrated Control System

In blow molding machines, especially extrusion blow molding, the integrated control system (sometimes called a wall thickness controller or parison control unit) handles:

Wall thickness profiling (controls how thick or thin the plastic is at different points)

Actuator or hydraulic control to adjust the die head

Start-up programs – which include all the machine parameters required to run a production cycle (heating zones, parison profile, timings, motor speeds, etc.)